Quality

The Cable Associates' commitment to quality is at the forefront of the processes, products and services that meet or exceed all customer requirements.

The Cable Associates quality engineering team primary focus is continued quality improvement as evidenced by the following:

- detailed quality control procedure handbook revised annually

- highly trained engineers / technicians

- state of the art equipment sourcing / regular maintenance and calibration

- BOM verification

- RoHS compliance verification

- First article verification both standard and AS9102B forms

- Drawing rev level verification

- Cut sheet verification

- Test setup verification

- Previous build notes verification

- Internal documentation (drawings, procedures, travellers, test sheets, schematics)

All Cable Associates electrical cable assemblies are tested 100% for continuity and signal integrity. Fiber optic - Copper - RF cable assemblies are tested following customer specific requirements.

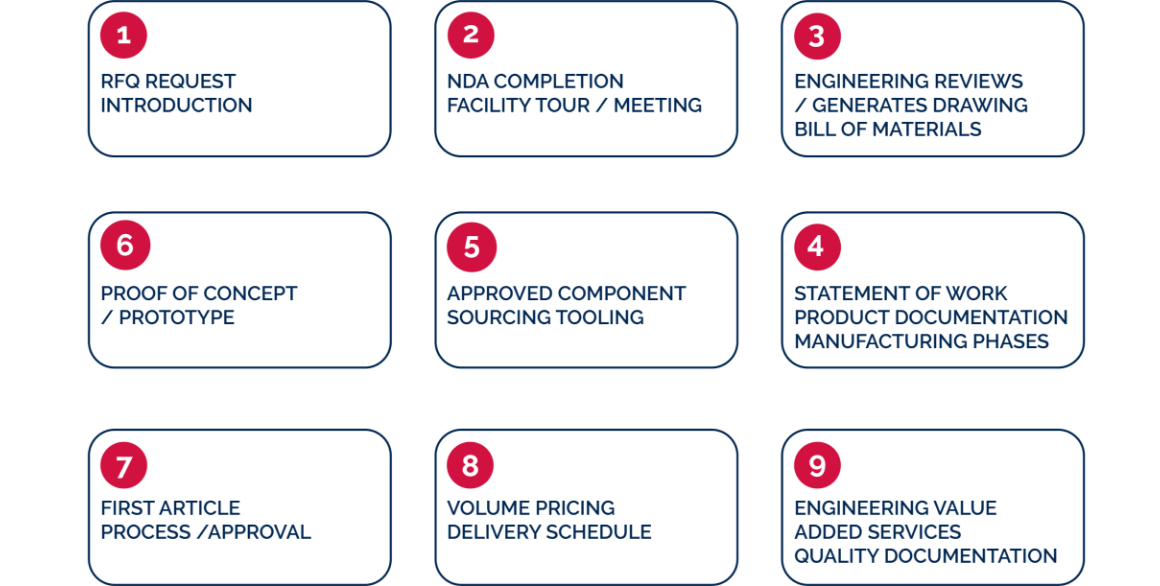

RFQ Process

Our Process

RFQ REQUEST INTRODUCTION

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

NDA COMPLETION

FACILITY TOUR / MEETING

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

ENGINEERING REVIEWS / GENERATES

DRAWING BILL OF MATERIALS

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

STATEMENT OF WORK PRODUCT

DOCUMENTATION MANUFACTURING PHASES

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

APPROVED COMPONENT

SOURCING TOOLING

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

PROOF OF CONCEPT / PROTOTYPE

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

FIRST ARTICLE PROCESS / APPROVAL

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

VOLUME PRICING DELIVERY SCHEDULE

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

ENGINEERING VALUE ADDED SERVICES

QUALITY DOCUMENTATION

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Certifications

AS9003

UL, COMPONENT - PROCESSED WIRE E514038

UL, PROCESSED WIRE E514038

IPC-J-STD-001

IPC/WHMA-A 620

ITAR Compliant

Equipment List

Cable Associates is continually expanding production and test capabilities with the latest manufacturing and test equipment. CAI monitors industry trends while working closely with our equipment suppliers and customers. From Schleuniger Mercury 4 Laser Wire Strippers to 40 GHz Anritsu Shockline VNA's, Cable Associates is committed to providing the highest quality cable assembly solutions for our valued customers.

Schleuniger cut and strip machines

TE, Molex, Positronic, Hirose, strip and crimp presses

JBC, Weller and Metcal Soldering stations

Hexacon & AB Industrial Solder Pots

Cirris & Fluke cable test systems

Custom assembly and test fixtures

TE, Molex, Hirose, Positronic, Amphenol crimp presses and tooling.

Schleuniger and Komax cut and strip machines

Panduit, Brady and TE Label systems

Cirris, Fluke and Schleuniger test equipment

Domaille & SGI Polishing machines and plates

Schleuniger automatic fiber production machines

Nordson Performus III epoxy dispensers

Temperature controlled curing ovens and stations

Viavi, Noyes, Opto-Test, EXFO and Rifocs optical test equipment

Viavi Inspection scopes and software

Viavi MAP 200/300 Fiber Mapping and Test Systems

Fiber Check II Inspection Scopes and Systems

Clean-Blast Cleaning Systems

Daisy, Norland and DORC Interferometers

Anritsu OTDR

Daisy D-Scope MT Fiber Optic Inspection System

Three ESD controlled laboratories with humidity control

ESD Monitoring systems

ESD Ionizers, benches, chairs and flooring

Tenney and Thermo-Tron Temperature Chambers

Schleuniger Pull Test equipment PT-28, PT26 and PT-326

40 GHz Anritsu vector network analyzers

Mini Circuits RF switching systems

Fiber Optic epoxy thermal ovens

Komax Mira 340 & 440, Comic 48R coax cutting systems

Komax Mira 230 wire stripping machines

Seven Associates T-500 Coax Cutter

Winton WX-6 semi rigid coax bending machines

Dimension Fiber scopes

Agilent 8753E Vector Network Analyzer

EXFO sources and power meters

OptoTest OP 735-IN3 & OP 950mm Power and back reflection meters

OptoTest 1x12 bi-directional switch matrix OP721-MM

Agiltron 1x24 and 1x12 optical switches1050 semi rigid strip machine

Schleuniger Unistrip 2600 strip machine

Schleuniger SR-1050 coax stripper

Schleuniger Mercury 4 laser wire stripper

Craftbot IDEC XL 3D Printer

TE RBK-X1 Heat Shrink Machines

TE XB-19 Heat Shrink Machines

Cole Parmer Ultra sonic cleaning machines

Brady Wrapter A6500 wrap around label machines

Brady Wrapter A6200 wrap around label machines

Siglent Function Arbitrary Waveform Generator SDG1032X

Siglent Digital Oscilloscope SDS-1202X-E

In-house designed test systems for laser testing.

Meiji Microscopes

Various in-house calibration equipment

Am-Scope MU1000 digital Inspection Microscope

Mountz TL-100i and various torque wrenches and screw drivers

Schleuniger 7010 Kevlar Cutters

LANTEK-II and Fluke CAT 5, 5e, 6 and 6A testers.