Contract Manufacturing Services

Cable Associates specializes in providing high-quality contract manufacturing services for commercial, industrial, and military applications. We deliver fully assembled fiber and copper assemblies tailored to meet each customer's specific requirements.

Our assemblies are RF piped, electrically wired, spliced, and rigorously tested to ensure full compliance with customer specifications. By partnering with us, clients benefit from:

• Reduced installation time

• Minimized quality issues

• Lower on-site labor costs

• Improved system integrity

• Decreased risk of equipment misplacement

With over 35 years of experience, our contract manufacturing team has successfully integrated products into a wide range of enclosures, including:

• 19” rack cabinet assemblies

• 1RU chassis

• Plug-in modules

• Harsh environment NEMA-rated enclosures

We collaborate closely with customer engineering teams to support product improvement initiatives, while also delivering comprehensive assembly and testing documentation as needed.

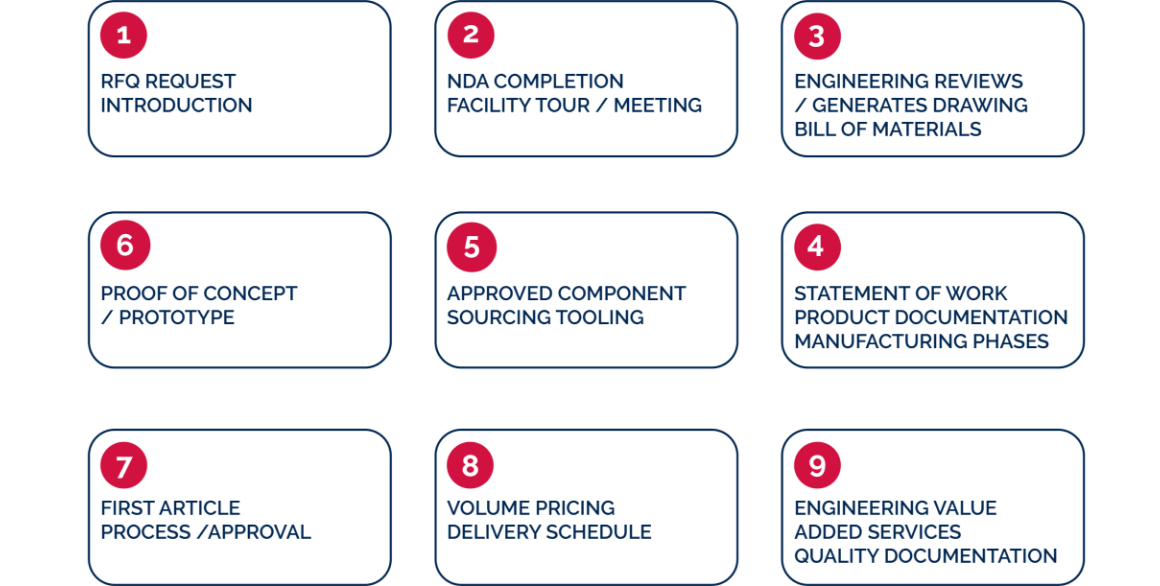

Contract Manufacturing Process

Cable Associates Inc. provides turnkey procurement solutions through manufacturing and testing of Fiber Optic, Copper and RF assemblies integrated into higher level sub-assemblies or finished goods. Our Contract Manufacturing division saves our customers time, resources and money in the manufacturing of their end products.

Contract Manufacturing Capabilities

Rack and Stack System Prefabrication

19”/23” EIA Rack

NEMA Weatherproof Chassis Integration / Assembly

- Component soldering

- Through hole PCBA soldering

- Module Installations

- RF and Optical testing

- Fiber optic splicing, routing and cabling

- RF routing and cabling

- Rack and chassis testing

Optical Component Termination

- Laser Termination

- Photodiode Termination

- Custom MTP/MPO Mapping and design

- Laser and photodiode testing available.

Transceiver Module Termination

- Transceiver Termination

- Transceiver testing

Optical Breakout Modules

- MTP/MPO to LC/SC breakout modules

- 19”& 23” Rackmount MTP/MPO breakout and shuffle chassis

Electro Static Discharge (ESD) Production Areas

- Two ESD labs with humidity control and ESD tile flooring

- ESD benchtops and Ionizers.

EST Labs Implemented For Handling

Optical Fusion Splicing

- 12 fiber ribbon and single fiber fusion splicing.

- Optical splitter chassis modules with internal fusion splicing

- Potting available upon request

RF Testing

- Up to 40GHz, full s-parameters testing

- Four Vector Network Analyzers

- RF Coax bending machine for forming semi-ridge RF cables

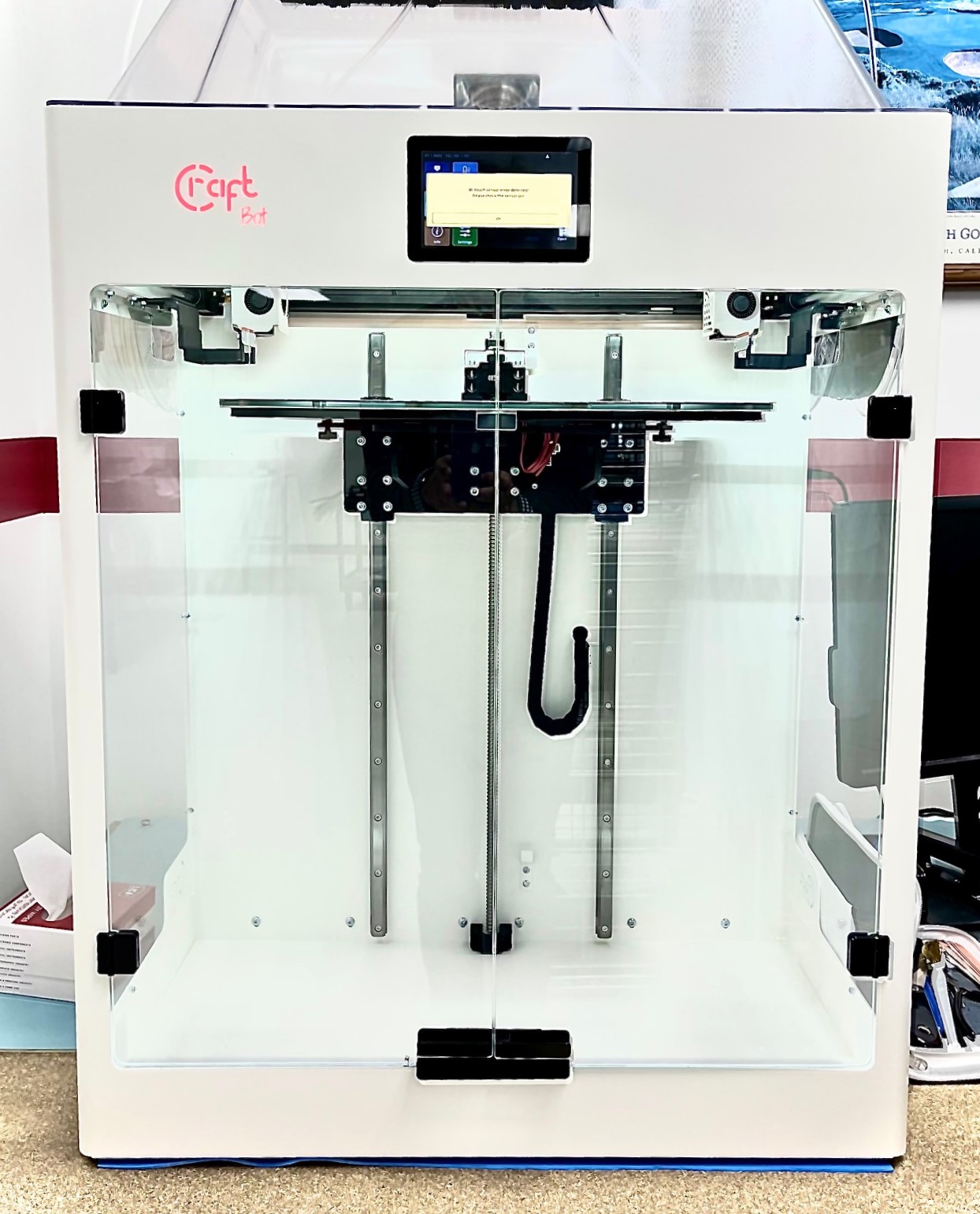

Cable Associates, Inc. continues to expand our product development capabilities with an investment in 3D Printing.

Our Craftbot IDEX XL dual head 3D printers give CAI the capability to print fiber optic fixtures and hardware used in cable assemblies with an impressive layer resolution of 50 micron.The many advantages include rapid prototyping, tangible design / product testing, and faster production times while cost effectively minimizing waste.

With a vast array of high temperature filament types and large printing area, Cable Associates is positioned to provide our customers with state of the art custom prototypes and designs.